Why Choose a professional coating for your garage or space?

Choosing a professional concrete coating system offers a combination of durability, aesthetic appeal, protection, safety, and cost-effectiveness. Whether for residential, commercial, or industrial spaces, a professionally applied coating can extend the life of your concrete surfaces while enhancing their appearance and functionality. Let’s chat about your project! Our team of dedicated experts are here to help and guide you to ensure your project is a success.

understand our process

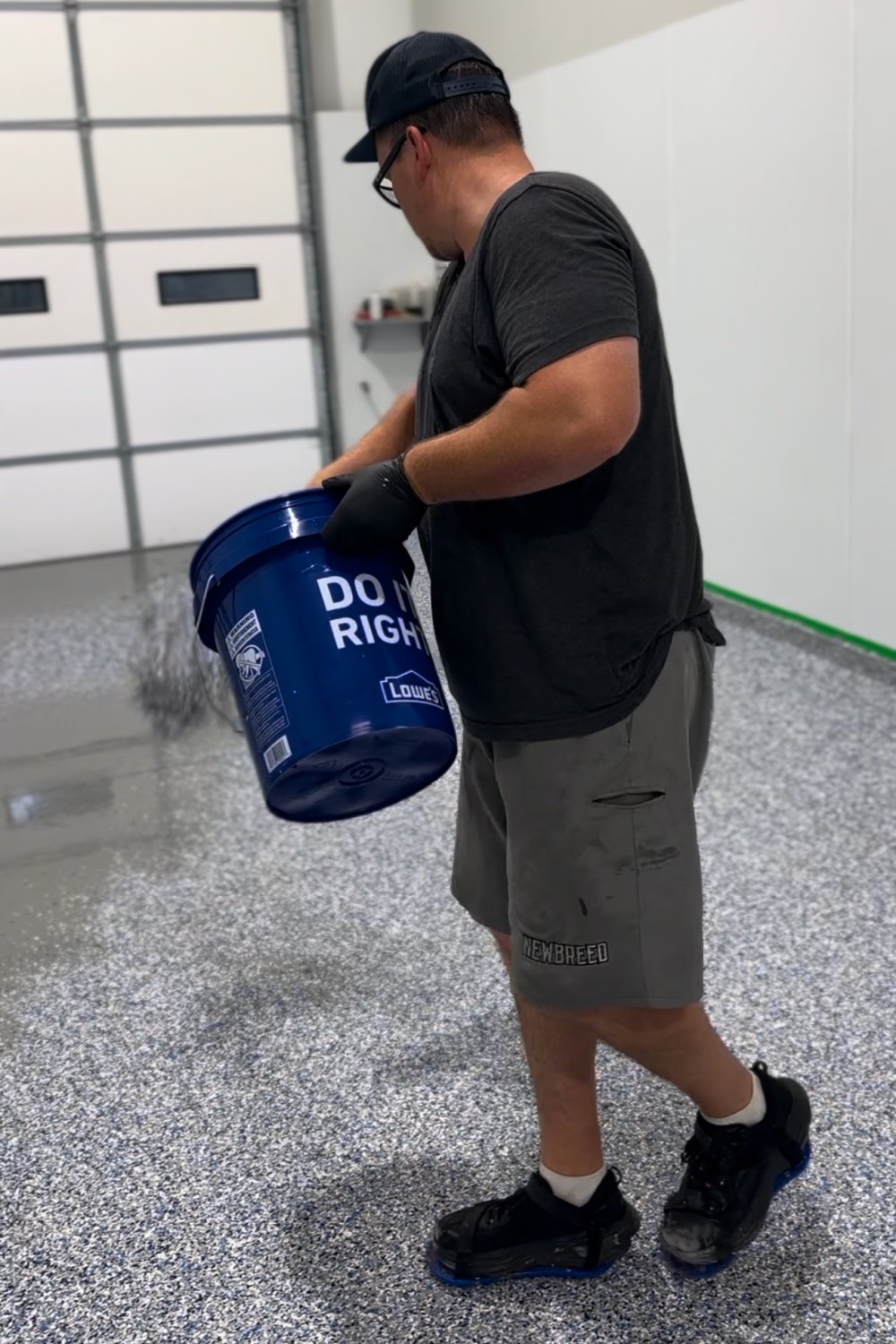

Grind

Surface Preparation

Surface prep is the most important aspect of any professional flooring system for maximum adhesion and bond. We begin by grinding your concrete floor utilizing walk-behind diamond floor grinders. All of our are grinders are attached to HEPA-filtrated, industrial vacuum systems which capture the majority of the dust created throughout the process. A pure surface is key, which allows our coatings to penetrate deep into the substrate and create a long lasting bond. After the grinding is complete, a thorough vacuum of the surface is performed to ensure a clean and beautiful bond for our concrete system. These step are crucial, which is why we do them on every floor that we do!

Base

Base coat application

Our clients deserve the best, which is why we offer the highest-quality products available for both commercial and residential applications. We ensure maximum durability by selecting the best base products, tailored to each project’s specific needs. The choice of materials depends on the substrate—whether it's floors, cinder blocks, or wood—ensuring the right solution for every surface. Over the years, we've successfully protected a wide variety of surfaces with consistent, uniform finishes. As a small business, we focus on delivering exceptional quality, leveraging our experience to exceed customer expectations with every project we undertake.

Flake

Flake Application

As customers, you can fully customize the color of the flake for your floor. The decorative flakes are carefully hand-applied to the wet basecoat, allowing them to chemically bond with the polyurea for a smooth and beautiful finish. This process helps mask minor imperfections in the concrete, adding both durability and impact resistance. If you're working in a wet environment or want anti-slip properties, we can incorporate that into your system as well. After the flakes have set, we return to level them with a scraper, reclaim the flakes, and vacuum the surface before applying the final polyaspartic topcoat. Once this step is completed, your project is nearly finished, with all solutions tailored to your specific needs.

The Final Step

Polyspartic Top Coat

Polyaspartic coatings are durable and resistant to wear, providing long-lasting protection against abrasions, stains, chemicals, and UV damage. They're ideal for high-traffic areas like garage floors, industrial settings, and commercial spaces. One of their key advantages is fast curing, often within 1 to 2 hours, compared to traditional epoxy coatings that can take 24-48 hours. This allows for quicker project completion. UV stable, polyaspartic coatings won’t yellow or degrade in sunlight. They also provide a glossy, high-shine finish that is easy to clean and resistant to staining from oils, chemicals, and other substances. We've seen excellent results in applications such as home garages, storage units, and wash bays, making them a great final touch for any project.

Flake Options

IN STOCK BUT NOT LIMITED TO...

NIGHTFALL

Nightfall maintains consistent popularity. The combination of greys and a hint of black offers a versatile blend for different environments.

DOMINO

Domino adds contemporary elegance to any space, infusing it with depth and character, while complementing various design styles. Perfect for high-traffic areas or statement floors, it leaves a lasting impression with its captivating color palette.

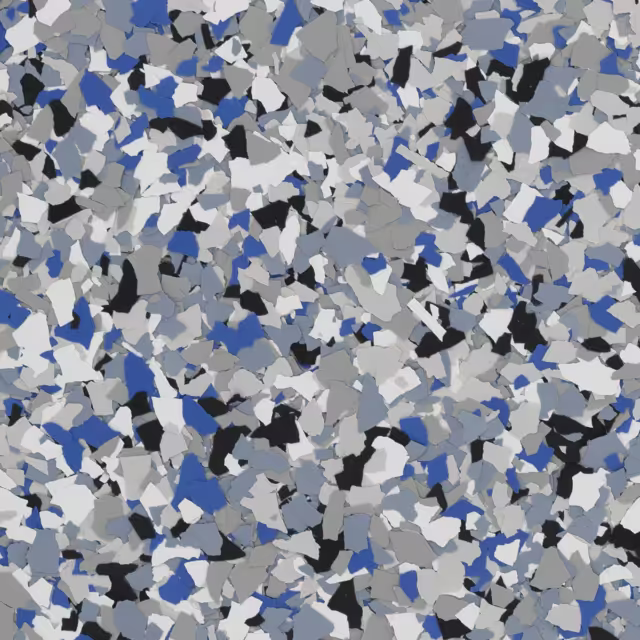

COMET

Comet offers a bold flooring solution with white, grey, and black hues accented by blue. Ideal for modern spaces.

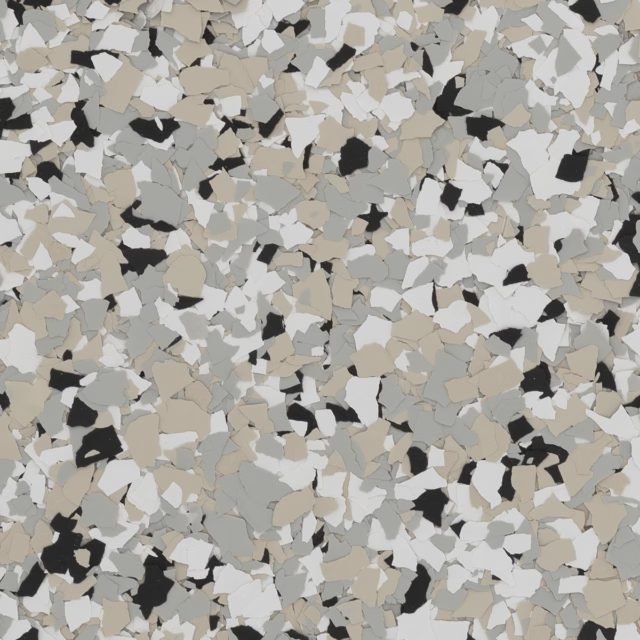

CABIN FEVER

Cabin Fever is a laid-back, soft, and balanced combo flaunting posh hues of white, gray, and brown paired with sleek black touches. A top pick for revamping living and work areas, it introduces a cozy and classy feel, enhancing the mood of any project with its chic color combo.

CREEKBED

Creekbed blend showcases earthy colors like beiges, browns, and greys, evoking nature's beauty with warm tones.

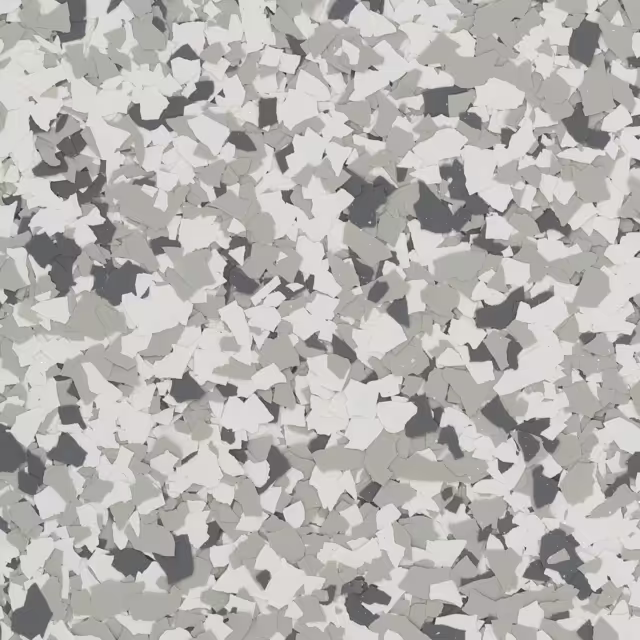

snowfall

Snowfall harmoniously combines cool grays and crisp whites, creating a versatile color palette that complements various design styles.

shoreline

Shoreline is a subtle, light, and neutral decorative blend ideal for various flooring applications, harmoniously blending browns and blacks for commercial and residential spaces.

SADDLE TAN

Saddle Tan combines white, brown, and black hues for a timeless ambiance in any space. Its balanced palette enhances aesthetics, offering a bold yet refined atmosphere.

Hybrid blend options

Carbon

Sophisticated black and gray blend, perfect for enhancing interior aesthetics.

Lanai gray

Lanai Gray presents a mixed palette of gray and white tones strategically designed to introduce sophistication and enduring attractiveness to diverse flooring projects. With its distinct and artistic flair, Lanai Gray enriches the beauty of interior spaces and stands out as the preferred option for individuals seeking a refined flooring solution.

Dolerite

Dolerite blends grey and brown tones for a timeless appearance. Its refined design enhances any space, making it ideal for flooring applications in commercial or residential settings.

soapstone

REQUEST A QUOTE

FAQs

How long does the installation process take?

Typically, we are able to prep, install and do final touches in 1 full day. Depending on the size of the space and the complexity of the job, it could end up being 2 days. We will communication the process thoroughly so you are aware of our process and can plan accordingly.

How long will the floors last?

Our flooring system can last 10 to 20 years or more, depending on several factors. Here are the key elements that affect the lifespan of an a professional flooring system

Quality of the Product: Higher-quality products tend to last longer. Professional-grade coatings may offer a longer lifespan than DIY options.

Usage: High-traffic areas or spaces exposed to heavy machinery, chemicals, or intense wear may require re-coating sooner. Commercial or industrial environments usually see shorter lifespans compared to residential spaces.

Maintenance: Regular maintenance, such as cleaning and minor repairs, can extend the life of an epoxy floor. Avoiding harsh chemicals and abrasives helps preserve its appearance and function.

Environmental Factors: Exposure to UV light, temperature fluctuations, or moisture can impact the lifespan.

If well-maintained, a professional flooring system can often last for decades, providing a durable, low-maintenance surface.

What are the benefits of a professionally installed concrete coating?

Durability: Our flooring system is resistant to wear, heavy traffic, and impact.

Chemical Resistance: Professional coatings can withstand a wide range of chemicals, making them ideal for garages, laboratories, and industrial areas.

Easy to Clean: Smooth surface, easy to maintain and clean.

Aesthetic Appeal: Available in a variety of colors and finishes, including metallic, flake, or solid color options.

Safety: Concrete floor coatings can be made slip-resistant with additives. If non slip is what you’re after, please let us know!